Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: PT124-35MPa-1/2-6/18-SIL

Place Of Origin: China

Warranty: 1 Years

Customized Support: Oem, Obm

Place Of Origin: Guangdong, China

Model Number: Pt124

Pressure Range: 0-10Bar.....1500Bar optional

Output: 4-20 mA; 0-10V; 2mv optional.

Power Supply: 24V DC

Pressure Type: Gauge pressure

Material: Stainless Steel

Electronic Connection: Fixed cable Explore proof and water proof IP67...

Process Connect Port: 1/2''-UNF Male, M10*1, M14*1.5, M20*1.5

Warranty Period: 3 Years

Support Customization: Oem, Odm, Obm

Product Name: High temperature melt pressure sensor

Certificate: Ce Certificate

Packaging: carton

Transportation: Ocean,Land,Air,Express,Others

Supply Ability: 1000

Payment Type: L/C,D/P,D/A,T/T,MoneyGram

Incoterm: FOB,CIF

Melt Pressure Sensor/Melt pressure transmitter description

Melt pressure sensor PT series flexible standard high temperature melt pressure transmitter from Xiaogan Yueneng Electronic Technology Co., LTD. 150-380 degrees Celsius high temperature is widely used in a variety of plastic extruder melt pressure sensor, rubber extruder high temperature melt transmitter used in industrial environment, melt pressure transmitter can be used seamlessly with PY9000 series intelligent digital pressure gauge produced by our company and similar control instrument analogy Dynisco14800, Thus, accurate measurement and effective control of pressure parameters can be achieved. The melt pressure transmitter is equipped with an advanced 4-20mA amplifier circuit, which can amplify the collected melt pressure sensor signal, making the signal more stable and reliable. The amplified signal can be directly input into the PLC control system, which is convenient for users to carry out automatic control and data processing.

In addition, Xiaogan Yueneng Electronic Technology Co., Ltd. PT124 series of flexible tube standard melt pressure transmitter is integrated with 80% calibration signal, which means that users can more easily calibrate during use to ensure the accuracy of measurement results. Because of its excellent performance and reliability, this series of products has been widely recognized and applied in the domestic market. Especially in the extrusion industry such as plastics and rubber, the advantage of the melt pressure transmitter is particularly obvious, it can provide accurate and reliable melt pressure measurement data, help users optimize the production process, improve product quality and production efficiency.

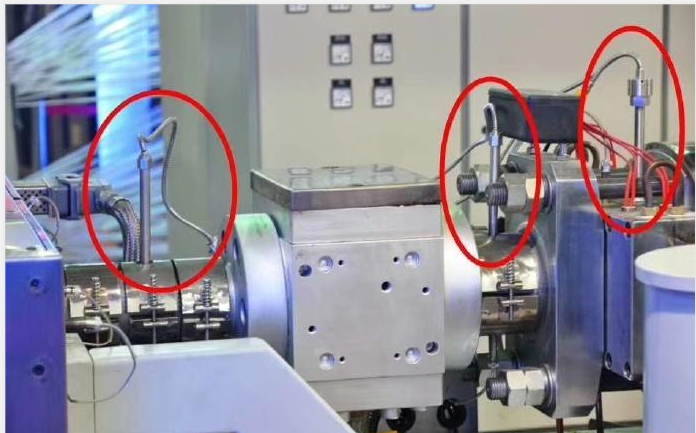

Engineering renderin

When choosing a melt pressure sensor for melt pressure transmitter applications, there are several important factors to consider

1. Compatibility with Liquid Type: Ensure that the melt pressure sensor is suitable for the specific type of liquid you will be measuring. Different liquids have different properties, such as viscosity and corrosiveness, which may require different sensor materials or designs. Consider factors such as the chemical compatibility of the melt pressure sensor with the liquid to ensure accurate and reliable measurement.

2. Accuracy and Precision: Look for a melt pressure sensor that offers high accuracy and precision. This ensures that the measurements are reliable and can be used for precise control and monitoring of the liquid system. Consider the melt presure sensor's specifications, such as the measurement accuracy and resolution, to ensure that it meets your requirements.

3. Construction and Material: Choose a melt pressure sensor with a construction that is suitable for liquid applications. Opt for materials that are resistant to corrosion and can withstand the melt pressure and melt temperature conditions of the liquid. Stainless steel or other corrosion-resistant materials are commonly used for liquid melt Pressure Sensors.

4. Seal and Protection: Liquid melt pressure sensors need to be well-sealed to prevent any leakage or ingress of liquid into the sensor. Look for sensors with reliable seals and appropriate protection ratings, such as IP65 or higher, to ensure the melt pressure sensor remains protected in wet or harsh environments.

5. Electrical Output and Communication: Determine the electrical output signal of the pressure sensor and ensure compatibility with your existing control system or data acquisition setup. Common output signals include 4-20mA, 0-10V, or digital communication protocols like Modbus or Ethernet.

1.How to place an order ?

Product Categories : High Temperature Pressure Sensors > Melt Pressure Transducers

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.